Choosing the right biscuit production line is a critical decision for any biscuit manufacturer planning to improve efficiency, expand capacity, or ensure consistent product quality.

With various biscuit types, production technologies, and automation levels available on the market, selecting the most suitable solution requires careful evaluation of several key factors.

Understand Your Biscuit Product Requirements

The first step in choosing the right biscuit production line is clearly defining the type of biscuits you plan to produce. Each biscuit product requires its own production process and suitable equipment configuration.

Common biscuit categories include:

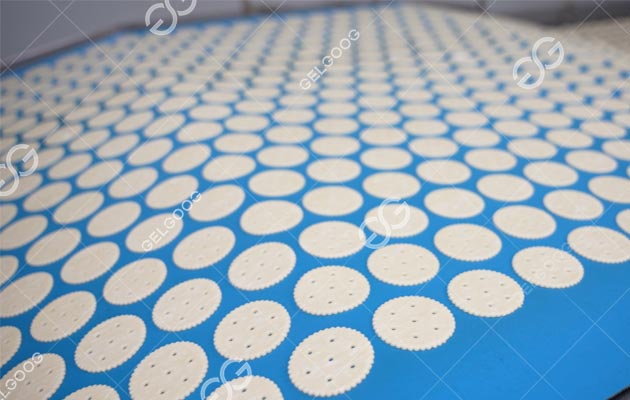

- Hard biscuits and crackers

- Soft biscuits and cookies

- Cream-filled biscuits

- Sandwich biscuits

Each category requires specific biscuit forming machines and baking technologies. If you have a limited budget and want to maximize the utilization of your production line, you can consider a multi-product line solution. Understanding your needs helps determine the correct biscuit processing solution from the start.

Evaluate Production Capacity and Output Needs

Production capacity is another key factor when choosing a biscuit manufacturing line. Manufacturers should assess current demand as well as future expansion plans.

Important capacity-related questions include:

- Required output per hour

- Number of production shifts

- Expected growth over the next few years

Choosing a scalable biscuit production machine allows manufacturers to increase output without major equipment replacement. Overestimating capacity may result in unnecessary investment, while underestimating can limit business growth.

Consider the Level of Automation

Automation plays a major role in modern biscuit production lines. Higher automation levels reduce labor dependence, improve consistency, and enhance operational stability.

- Typical automation features include:

- PLC control systems

- Automatic dough feeding and forming

- Continuous tunnel ovens

- Automated cooling and stacking systems

A fully automatic biscuit line is ideal for factories focusing on high efficiency and standardized output. Semi-automatic systems may suit operations requiring more flexibility or manual intervention.

Key Equipment in a Biscuit Production Line

- Dough mixing system

- Dough forming or molding machine

- Baking oven (tunnel oven or rotary oven)

- Cooling conveyor

- Packaging machine

Each piece of biscuit production equipment should be matched to the dough characteristics, biscuit shape, and baking requirements. Equipment compatibility and process continuity are essential for stable operation.

Supplier Experience and Technical Support

Choosing the right equipment supplier is as important as selecting the production line itself. An experienced supplier can provide complete solutions, from process design to installation and after-sales support.

When evaluating biscuit line suppliers, consider:

- Industry experience and references

- Customization capability

- Technical documentation and training

- Long-term service and spare parts support

Reliable technical support ensures stable operation throughout the lifecycle of the biscuit making equipment.

Choose the right biscuit production line requires a comprehensive evaluation of product type, capacity, automation level, equipment configuration, and supplier expertise. Then this production line helps manufacturers achieve efficient production, consistent quality, and sustainable long-term growth.