What is a biscuit oven? It’s a continuously operating, industrial-grade baking machine. Its core concept is a long, precisely temperature-controlled tunnel with a slow-moving conveyor belt (usually a steel or mesh belt) inside.

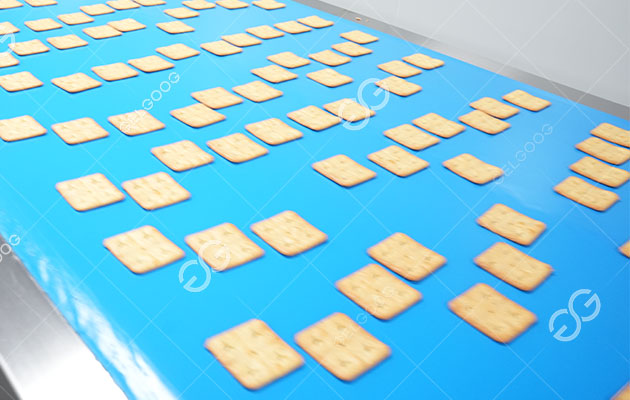

The conveyor belt carries the formed biscuits through a tunnel spanning tens or even hundreds of meters. Where they undergo a series of baking stages, ultimately transforming into golden, perfectly hydrated, and crispy finished products at the other end.

The key difference between this biscuit tunnel oven and a rotary oven lies in its continuity and precise control. While rotary ovens bake in batches, industrial biscuit ovens operate 24 hours a day. They can produce tons of product per hour and precisely control the temperature, humidity, heat transfer, and airflow in every zone within the oven.

How Does A Biscuit Oven Work?

1.Feeding

After undergoing previous steps (such as rolling and forming), the raw dough is evenly placed on a moving conveyor belt and then enters the baking oven. The conveyor belt speed determines the time the biscuits spend in the oven, which is the primary factor controlling the degree of baking.

2.Heating, Four Temperature Zones

①Preheating Zone (First Zone): After entering the industrial biscuit oven, the biscuit dough is first heated evenly at a low to medium temperature (approximately 160-180°C). During this stage, the bottom heat (conduction heat) primarily sets the shape of the biscuit base, while gentle convection heat warms the dough overall, preparing it for subsequent reactions.

Expansion Zone (Second Zone): As the temperature rises, the moisture in the dough evaporates into steam, and the leavening agent (such as baking soda) decomposes to release carbon dioxide. This gas is trapped by the gelatinized starch, causing the biscuits to expand rapidly. Uniform heating is essential during this stage to prevent premature crusting on the surface.

③Dehydration Zone (3rd Temperature Zone): The temperature reaches its highest point (approximately 200-220°C), where strong convection heat efficiently evaporates moisture from the biscuits’ interior, solidifying their structure. An exhaust system removes moisture and prevents condensation. The biscuits transition from steamed to baked, achieving a crispy texture.

④Coloring Zone (4th Temperature Zone): The temperature drops slightly (approximately 180-200°C). Radiant heat from the upper heating zone concentrates on the biscuit surface, triggering the Maillard reaction and caramelization, resulting in a golden color and rich aroma. Precise temperature control ensures the perfect color and flavor.

3.Exit and Cooling

The baked biscuits exit the other end of the oven. At this point, they are still very hot and soft. They are immediately conveyed to a cooling line, which is often two or three times the length of the oven. Here, the biscuits cool naturally in room temperature air for about 10-20 minutes, allowing their internal structure to solidify, become crispy, and reach the stable temperature required for packaging.

What is a biscuit oven? As one of the most crucial equipment in a biscuit production line, the industrial biscuit oven’s importance lies not only in its efficient and continuous production capabilities, but also in its direct influence on the core quality and flavor of the product.