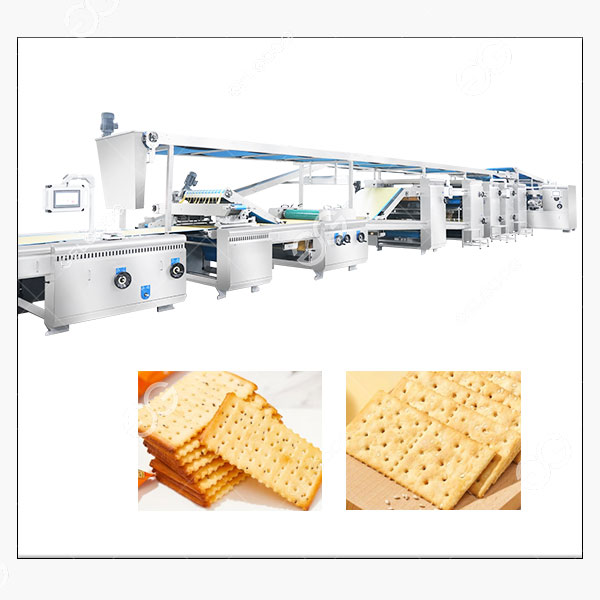

Our automatic biscuit making plant integrates every stage from dough prep, forming and baking through cooling and final packaging, guaranteeing premium quality and flawless appearance.

You can fully tailor the modular line to hit exact recipe targets. To produce hard biscuits, soft biscuits, butter cookies, soda crackers, or cream-filled sandwiches on demand.

Features of Automatic Biscuit Plant

1.Fully Automated Biscuit Production Process

- Dough Mixing & Feeding: High-speed industrial mixers ensure uniform dough consistency.

- Forming & Molding: Rotary or wire-cut molding machines for different biscuit shapes (round, square, custom designs).

- Baking System: One of the important equipment of the automatic biscuit making plant. Multi-zone tunnel oven with precise temperature control for even baking.

- Cooling Conveyor: Efficient cooling to maintain crispness before packaging.

- Automatic Packaging: Flow wrapping, pouch packing, or tin filling options.

2.High Production Capacity

- Output ranges from 100 kg/hr to 1200 kg/hr, depending on configuration.

- This biscuit plant is suitable for small, medium, and large-scale biscuit factories.

3.Customizable Options

- Adjustable thickness, shape, and size for different biscuit types.

- Optional chocolate coating, cream filling, or icing systems.

- Compatible with gluten-free, sugar-free, and fortified biscuit recipes.

4.Energy-Smart & Built to Last

- Hybrid gas-electric ovens cut power use; food-grade stainless frame resists corrosion and wipes clean in seconds.

- One PLC panel runs and watches every zone with fingertip ease.

Advantages Over Competitors – Automatic Biscuit Making Plant

✔ Turnkey Solution – We provide installation, training, and after-sales support.

✔ Flexible Customization – Adaptable to different biscuit types and market needs.

✔ Reliable Performance – Built with European & Japanese components for minimal downtime.

✔ Competitive Pricing – More cost-effective than similar plants from Western suppliers.

Why Is This Biscuit Plant a Hot-Selling Product?

✅ High Demand for Biscuits – The global biscuit market is growing rapidly, creating opportunities for manufacturers.

✅ Low Labor Costs – Automation reduces dependency on manual workers, cutting operational expenses.

✅ Quick ROI (Return on Investment) – High-speed production ensures fast payback periods.

✅ Export Potential – Many countries import biscuits, making this a profitable business model.

Get Your Biscuit Plant Today!

Purshase in an Automatic Biscuit Making Plant to boost production efficiency, reduce costs, and maximize profits.

📞 Contact us now for a FREE quote & factory layout design!

📧 Email: [lisa@machinehall.com]

🌐 Website: [www.biscuitprocessing.com]

📍 Location: [Zhengzhou City, China]

💬 WhatsApp: [+8615515571373]

Technical Parameters

| Model | Capacity | Inner Width of Tunnel Oven | Heating Method | Dimensions (without packing machine) |

Voltage |

| GG-BG400/420 | 100-250kg/h | 400/420mm | Electric,Gas | L45m*W5m*H2m | 380V 50HZ 3PH |

| GG-BG600 | 250-400kg/h | 600mm | Electric,Gas | L50m*W5m*H2m | 380V 50HZ 3PH |

| GG-BG800 | 500-800kg/h | 800mm | Electric,Gas,Diesel | L100m*W5m*H2.5m | 380V 50HZ 3PH |

| GG-BG1000 | 800-1000kg/h | 1000mm | Electric,Gas,Diesel | L105m*W12m*H3m | 380V 50HZ 3PH |

| GG-BG1200 | 800-1200kg/h | 1200mm | Electric,Gas,Diesel | L120m*W15m*H3m | 380V 50HZ 3PH |

Reviews

There are no reviews yet.