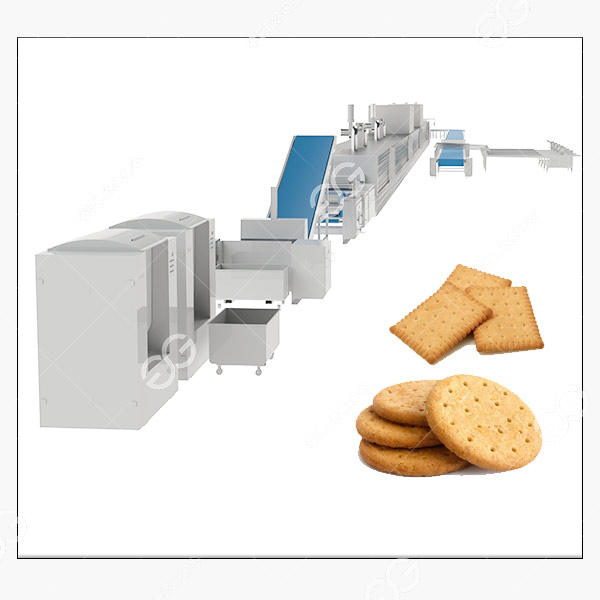

The bear biscuit production line is efficient and automated. It has the characteristics of good forming and large capacity, and can produce bear biscuits efficiently. The production line covers whole process from mixing to packaging, producing bear biscuits with uniform texture.

The production line has high-speed production and less manual intervention, so the biscuit yield is high. The flexible design can adapt to the production of various biscuit types, enhancing the product market competitiveness.

Features of Bear Biscuit Production Line

- The production line is equipped with a high precision weighing and feeding system that can accurately measure and feed various raw materials such as flour, sugar, butter, and cocoa powder according to preset recipes. This ensures consistent product quality and uniform flavor.

- It features an advanced dough mixing system with variable speed mixing and automatic lubrication functions. The high performance mixers can quickly and evenly blend the raw materials, producing dough with stable gluten and uniform texture.

- The shaping system utilizes premium food-grade molds with intricate bear shaped designs. These molds ensure biscuits have lifelike details and clear patterns, while being durable and easy to maintain.

- The baking system uses multi zone temperature control ovens with precise temperature control and uniform heat distribution. The ovens can automatically adjust the temperature and baking time according to different bear biscuit formulas and production requirements.

- The cooling system adopts advanced airflow technology and automatic temperature control to ensure even cooling of the bear biscuits. This prevents deformation, cracks, and other quality issues and ensures the bear biscuits maintain their shape and texture.

How Are Bear Biscuits Processed?

Advantages of Bear Biscuit Production Line

- Increased production efficiency: The production line can produce thousands of bear biscuits per hour, significantly improving your production capacity and meeting market demand.

- Reduced production costs: The automated production process reduces manual interventions and raw material waste, lowering labor and material costs.

- Improved product quality: The high precision equipment and advanced technology ensure consistent product quality and uniform appearance, enhancing customer satisfaction and market competitiveness.

- Enhanced product value: The intricately designed bear biscuits can attract more consumers and increase product value and market share.

- Stable production process: The reliable equipment and advanced technology ensure stable production operations and reduce production risks and downtime.

Our bear biscuit production line has received positive feedback from clients for its excellent performance, high quality, and reliable operation. Choose our production line, and you’ll be choosing a reliable partner for your business growth.

Technical Parameters

| Model | Capacity | Inner Width of Tunnel Oven | Heating Method | Dimensions (without packing machine) |

Voltage |

| GG-BG400/420 | 100-250kg/h | 400/420mm | Electric,Gas | L45m*W5m*H2m | 380V 50HZ 3PH |

| GG-BG600 | 250-400kg/h | 600mm | Electric,Gas | L50m*W5m*H2m | 380V 50HZ 3PH |

| GG-BG800 | 500-800kg/h | 800mm | Electric,Gas,Diesel | L100m*W5m*H2.5m | 380V 50HZ 3PH |

| GG-BG1000 | 800-1000kg/h | 1000mm | Electric,Gas,Diesel | L105m*W12m*H3m | 380V 50HZ 3PH |

| GG-BG1200 | 800-1200kg/h | 1200mm | Electric,Gas,Diesel | L120m*W15m*H3m | 380V 50HZ 3PH |

Reviews

There are no reviews yet.