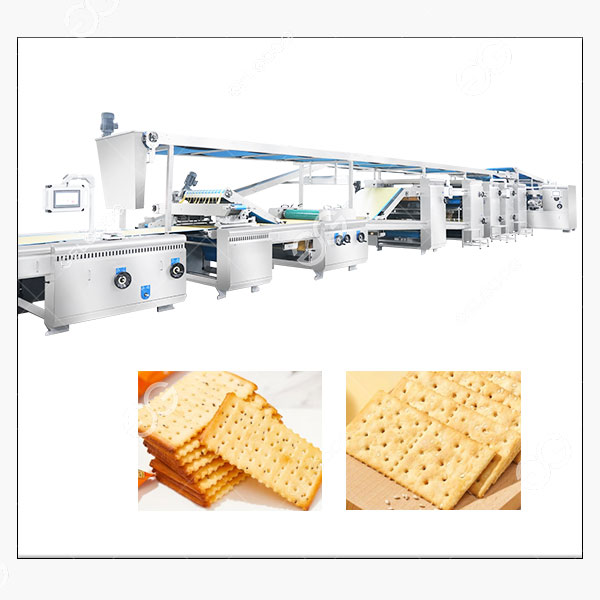

Our complete biscuit manufacturing equipment is an automated biscuit solution launched by our company for the global mid-to-high-end baking market. Delivered as a turnkey solution, it integrates dough processing, biscuit shaping, biscuit baking, cooling, and packaging.

Whether you plan to produce hard biscuits, chewy biscuits, soda crackers, or high-end products such as sandwiches and chocolate-coated biscuits, this equipment can complete product category conversion within 30 minutes through modular switching.

Features of Complete Biscuit Manufacturing Equipment

- All-stainless steel body with a smooth, easy-to-clean surface. The biscuit equipment meets multiple certifications including CE and ISO, satisfying export requirements in Europe and America.

- Human-machine interface with a large touchscreen. One-button switching of automatic biscuit manufacturing machinerecipe parameters allows for immediate production of hard biscuits, soft biscuits, soda biscuits, and sandwich biscuits.

- The tunnel oven is equipped with a waste heat recovery system, recycling heat energy and reducing gas consumption by approximately 18% compared to similar systems, resulting in significant energy savings.

- Key components such as the conveyor belt and nozzles can be quickly disassembled by hand. Single-point cleaning takes ≤5 minutes, effectively reducing biscuit equipment downtime and ensuring hygiene standards are met.

- The machine has a built-in remote diagnostic module supporting VPN encrypted connections. Engineers can adjust parameters and upgrade programs online, reducing travel costs.

Working Video of Automatic Biscuit Manufacturing Machine

Composition of the Complete Biscuit Manufacturing Equipment Set

This solution includes: dough mixer, dough cutter, elevator, three-roll reciprocating calender unit, roll forming machine/roll printing machine (with quick-change biscuit molds), waste material return elevator, gas/electric tunnel oven (length 30~90 m optional);

Cooling conveyor line/cooling tower, oil sprayer, powder sprinkler (sugar powder, salt powder, etc.), 180° flat turning machine, automatic material handling and stacking machine, high-speed biscuit pillow packaging machine/multi-head weighing packaging machine, as well as metal detection, automatic boxing, etc.

Services Provided by the Company

Our company not only provides complete biscuit manufacturing equipment, but also: free quotes, project feasibility assessments, CAD factory planning, and investment recovery analysis. We offer open workshop trials with materials to verify formulas and production capacity.

On-site installation and commissioning, with mass production delivery in as little as 20 days. One-year warranty on key components, ample spare parts inventory. 24-hour video technical support, remote upgrades and fault diagnosis, and lifetime service response.

We also assist clients in applying for export certifications such as CE, SONCAP, EAC, and SASO, and provide multilingual operation manuals and maintenance guides in English, Spanish, Russian, and other languages.

If you are looking for CE certified, exportable, and flexible complete biscuit manufacturing equipment capable of producing a variety of biscuits, this equipment is your cost-effective choice. Feel free to call or leave a message online, and we will provide you with the latest quote within 24 hours.

Technical Parameters

| Model | Capacity | Inner Width of Tunnel Oven | Heating Method | Dimensions (without packing machine) |

Voltage |

| GG-BG400/420 | 100-250kg/h | 400/420mm | Electric,Gas | L45m*W5m*H2m | 380V 50HZ 3PH |

| GG-BG600 | 250-400kg/h | 600mm | Electric,Gas | L50m*W5m*H2m | 380V 50HZ 3PH |

| GG-BG800 | 500-800kg/h | 800mm | Electric,Gas,Diesel | L100m*W5m*H2.5m | 380V 50HZ 3PH |

| GG-BG1000 | 800-1000kg/h | 1000mm | Electric,Gas,Diesel | L105m*W12m*H3m | 380V 50HZ 3PH |

| GG-BG1200 | 800-1200kg/h | 1200mm | Electric,Gas,Diesel | L120m*W15m*H3m | 380V 50HZ 3PH |

Reviews

There are no reviews yet.