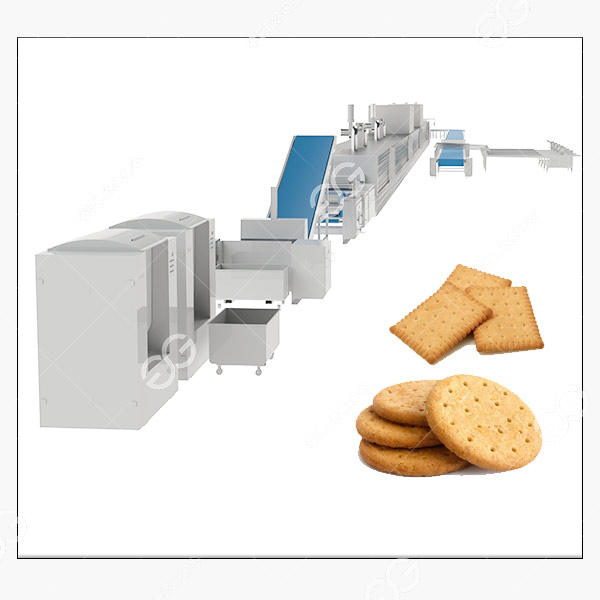

The biscuit production plant is a fully automated solution, it is suitable for industrial biscuit manufacturing. It handles the entire production process, from dough mixing to packaging, ensuring consistent product quality.

This automatic plant is suitable for producing various types of biscuits. Including hard biscuits, soft biscuits, sandwich biscuits, cookies, soda crackers, biscuit stick, compressed biscuits, ladyfinger biscuit, and more.

Technical Parameters of Biscuit Production Plant

- Voltage: 380V / 50Hz (customizable for different regions)

- Capacity: 200–1200 kg/h depending on configuration

- Material: Food-grade stainless steel for all contact parts

- Biscuit Types: Hard, soft, sandwich, cracker and more

- Automation: Fully automated with PLC control and touch screen interface

Main Components and Functions

- Dough Mixing Machine: Accurately mixes flour, sugar, oil, leavening agents and other ingredients to form a smooth, homogeneous dough. This is the first key step in the biscuit production plant.

- Dough Cutting and Pressing Machine: Cut the whole dough into cube, then press the dough into sheets of precise thickness. Typically from 0.6 mm to 0.8 mm, the thickness can be adjusted.

- Biscuit Forming Machine: Shapes the dough sheets into uniform biscuit pieces using roller cutting or stamping, with excess dough collected and recycled to minimize waste.

- Biscuit Tunnel Oven: Provides controlled baking with adjustable temperature zones to ensure even color, texture, and crispness.

- Cooling Conveyor: Cools the baked biscuits efficiently to maintain shape and quality before packaging in the automatic biscuit plant.

- Packaging Machine: Packs biscuits into boxes, bags, or other containers, extending shelf life and preparing them for distribution and sale.

Advantages of Biscuit Production Plant

- The dough mixing and sheeting machines ensure uniform thickness and texture, so each biscuit has consistent size, shape, and color.

- The fully automated plant reduces manual intervention, allowing continuous operation and higher output compared with semi-manual or traditional plant.

- Quick mold change and adjustable forming parameters enable the production of multiple biscuit types on the same line, reducing the need for separate equipment.

- In this automatic biscuit plant, excess dough from forming is automatically collected and recycled, lowering raw material costs.

- The tunnel oven’s adjustable temperature zones ensure even baking, preventing overcooked or undercooked biscuits and reducing rejected products.

- Centralized PLC control with touch screen interface simplifies operation, while modular design allows easy cleaning and maintenance, reducing downtime.

Video of Automatic Plant for Making Biscuit

After-Sales Support of Automatic Biscuit Production Plant

- Installation and Commissioning: Professional guidance for setup and start-up.

- Operator Training: On-site or remote training to ensure staff can operate efficiently.

- Spare Parts and Maintenance: Quick supply of replacement parts and maintenance instructions.

- Remote Technical Assistance: Online support for troubleshooting and process optimization.

- Customized Solutions: Tailored production line configurations to meet specific factory needs.

Technical Parameters

| Model | Capacity | Inner Width of Tunnel Oven | Heating Method | Dimensions (without packing machine) |

Voltage |

| GG-BG400/420 | 100-250kg/h | 400/420mm | Electric,Gas | L45m*W5m*H2m | 380V 50HZ 3PH |

| GG-BG600 | 250-400kg/h | 600mm | Electric,Gas | L50m*W5m*H2m | 380V 50HZ 3PH |

| GG-BG800 | 500-800kg/h | 800mm | Electric,Gas,Diesel | L100m*W5m*H2.5m | 380V 50HZ 3PH |

| GG-BG1000 | 800-1000kg/h | 1000mm | Electric,Gas,Diesel | L105m*W12m*H3m | 380V 50HZ 3PH |

| GG-BG1200 | 800-1200kg/h | 1200mm | Electric,Gas,Diesel | L120m*W15m*H3m | 380V 50HZ 3PH |

Leave Your Inquiry

Click to rate this post!

[Total: 1 Average: 5]

Reviews

There are no reviews yet.