The chocolate stick biscuit production line is a fully automated equipment. It is widely used by major biscuit manufacturers and other snack food manufacturers to produce crispy, evenly coated chocolate stick biscuits.

This line is far more user-friendly than conventional equipment. It produces chocolate stick biscuits with far greater size, shape, and chocolate coating uniformity than conventional equipment, ensuring that every biscuit meets quality standards.

Features of the Chocolate Stick Biscuit Production Line

- Fully automated production saves labor and reduces errors: the machines automatically form and convey the chocolate stick biscuits, cutting manual labor and speeding up production.

- High output easily handles large-volume orders: This chocolate stick production line can produce thousands of kilograms of chocolate stick biscuits per hour, meeting large-scale supply needs.

- Consistent biscuit size and even chocolate coating: Precise control of chocolate stick biscuit shape ensures the same coating thickness on each biscuit for a better presentation.

- Flexible adjustment: One machine can produce multiple products: The line can easily change molds and chocolate types to produce chocolate stick biscuits of different flavors and sizes.

- Hygienic, safe, and easy to clean: The manufacturer builds the chocolate covered stick biscuit line in strict accordance with food safety standards, and its stainless steel construction allows for seamless cleaning, cutting maintenance efforts.

What is Chocolate Stick Biscuits

Chocolate stick biscuits are a beloved snack, consisting of a crisp, lightly sweetened biscuit center enrobed in a layer of milk, dark, or white chocolate. Chocolate sticks are often enjoyed as a tea-time treat or a quick dessert.

The slender, stick-like shape of chocolate stick biscuits makes them easy to handle and perfect for dipping. What sets chocolate stick biscuits apart is their versatility. Some chocolate stick biscuits even feature decorative drizzles, sprinkles, or double-dipped coatings.

Chocolate Stick Production Line Process

1️⃣ Kneading: A mixer kneads flour, sugar, butter, and other ingredients into a smooth dough.

2️⃣ Forming: The extruder forms the dough into long, thin strips, and a cutter then automatically cuts the strips into sticks of standard lengths.

3️⃣ Baking and Forming: A tunnel oven allows the sticks to become crispy and fragrant. Precisely controlled temperature and time prevent them from burning.

4️⃣ Chocolate Coating: A chocolate coating machine evenly coats the sticks with chocolate. The thickness is adjustable to suit your needs.

5️⃣ Cooling and Hardening: A freezing tunnel rapidly cools the dough, creating a crispy outer shell.

6️⃣ Packaging and Shipping: An automatic packaging machine individually packages the chocolate sticks, sealing them against moisture.

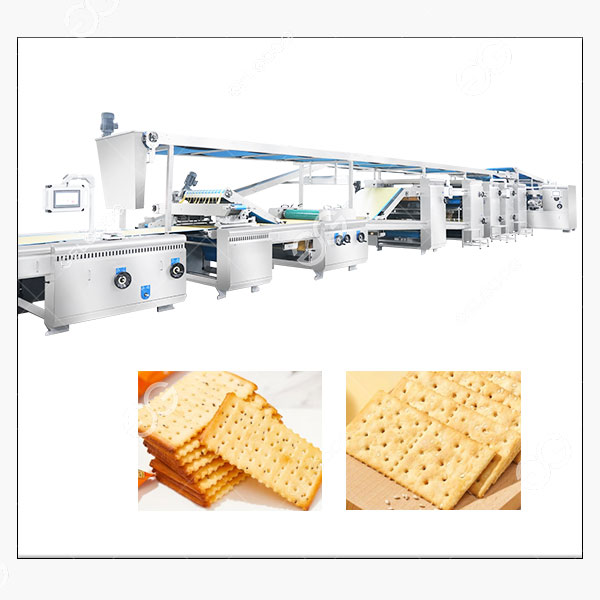

Main Equipment in the Chocolate Stick Biscuit Production Line

- Dough Mixer – For preparing uniform chocolate stick biscuit dough.

- Extrusion Machine – Shapes dough into sticks.

- Biscuit Baking Oven – Bakes chocolate stick biscuits to perfection.

- Chocolate Enrober – Applies a smooth chocolate coating.

- Cooling Tunnel – Cool the chocolate quickly.

- Packaging Machine – Seals and packs the final product(chocolate stick biscuits).

This chocolate stick biscuit production line provides a high-quality solution for a wide range of food manufacturers. Its automation, high precision, and scalability ensure consistent production while meeting industry standards. Whether you’re a major confectionery brand or snack manufacturer, this line is a reliable choice for producing high-quality chocolate stick biscuits.

Technical Parameters

| Model | Capacity | Inner Width of Tunnel Oven | Heating Method | Dimensions (without packing machine) |

Voltage |

| GG-BG400/420 | 100-250kg/h | 400/420mm | Electric,Gas | L45m*W5m*H2m | 380V 50HZ 3PH |

| GG-BG600 | 250-400kg/h | 600mm | Electric,Gas | L50m*W5m*H2m | 380V 50HZ 3PH |

| GG-BG800 | 500-800kg/h | 800mm | Electric,Gas,Diesel | L100m*W5m*H2.5m | 380V 50HZ 3PH |

| GG-BG1000 | 800-1000kg/h | 1000mm | Electric,Gas,Diesel | L105m*W12m*H3m | 380V 50HZ 3PH |

| GG-BG1200 | 800-1200kg/h | 1200mm | Electric,Gas,Diesel | L120m*W15m*H3m | 380V 50HZ 3PH |

Reviews

There are no reviews yet.