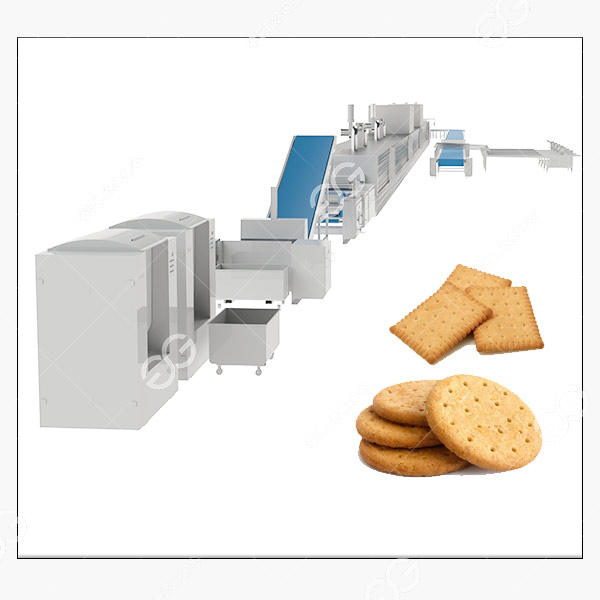

The compressed biscuit production line is engineered to transform simple ingredients (flour, grains, vitamins) into ultra-dense, long-shelf-life biscuits capable of withstanding extreme conditions.

Unlike standard biscuit lines, these systems prioritize high-pressure compaction and minimal moisture retention to achieve a hard texture and caloric density.

The compressed biscuit process integrates dough mixing, high-tonnage pressing, and vacuum-sealed baking critical for producing emergency rations, military field meals, and expedition snacks.

Features of Compressed Biscuit Production Line

- High-Pressure Multi-Stage Compactor: Hydraulic presses apply 50–80 tons of force per compressed biscuit, compressing dough into 90–95% density blocks in 3 progressive stages.

- Vacuum Baking Tunnel: Removes ambient moisture during baking, achieving <10% humidity for 3–5 year shelf stability.

- Nutrient Injection System: Precision pumps inject vitamins/proteins directly into dough mixers, ensuring uniform micronutrient distribution.

- Laser-Cut Portion Control: High-speed lasers cut compressed biscuits into exact caloric portions with zero crumb loss.

- Military-Spec Packaging Integration: In-line nitrogen-flushing and foil-sealing units block oxygen/humidity ingress, extending shelf life to 5 years.

Applications of Compressed Biscuit Production Machine

- Military & Disaster Relief: Produces 10,000+ compressed biscuits/hour for MREs (Meals Ready-to-Eat) with 5-year shelf life.

- Extreme Expedition Food: Creates high-calorie, lightweight compressed biscuits for mountaineering/arctic missions.

- Medical Nutrition: Fortifies compressed biscuits with protein/electrolytes for clinical use.

- Space & Marine Rations: Vacuum-sealed units resist humidity/salinity in oceanic or zero-g environments.

Video of Compressed Biscuit Production Line

Customization Capabilities

The compressed biscuit production line offers granular hardware customization to match diverse operational demands. Clients select from hydraulic press tonnage and laser-cutting templates to produce compressed biscuits in shapes ranging from compact cylinders to segmented tiles.

Simultaneously, the Cloud Recipe Management System stores over 50 formulations—adjusting nutrient profiles or allergen-free recipes (gluten/sugar substitutes)—with one-touch deployment. For specialized missions like Arctic expeditions, lines integrate ultra-low-moisture baking and cryogenic grinding for temperature-resistant ingredients.

Technical Parameters

| Model | Capacity | Inner Width of Tunnel Oven | Heating Method | Dimensions (without packing machine) |

Voltage |

| GG-BG400/420 | 100-250kg/h | 400/420mm | Electric,Gas | L45m*W5m*H2m | 380V 50HZ 3PH |

| GG-BG600 | 250-400kg/h | 600mm | Electric,Gas | L50m*W5m*H2m | 380V 50HZ 3PH |

| GG-BG800 | 500-800kg/h | 800mm | Electric,Gas,Diesel | L100m*W5m*H2.5m | 380V 50HZ 3PH |

| GG-BG1000 | 800-1000kg/h | 1000mm | Electric,Gas,Diesel | L105m*W12m*H3m | 380V 50HZ 3PH |

| GG-BG1200 | 800-1200kg/h | 1200mm | Electric,Gas,Diesel | L120m*W15m*H3m | 380V 50HZ 3PH |

Reviews

There are no reviews yet.