This ginger biscuits production line is a complete system is designed for ginger biscuits. It boasts high production efficiency, capable of producing an average of 300 kg of ginger biscuits per hour, or even more.

This machine is versatile, offering the advantage of “multiple products on the same line.” Purchasing a production line not only allows you to produce ginger biscuits, but also allows you to change molds, adjust parameters, and produce other biscuit styles.

What is Ginger Biscuits?

Ginger biscuits are a beloved treat worldwide. They are known for their warm, spicy flavor and satisfying crunch. These biscuits combine the sweetness of dough with the sharpness of ginger and other spices, such as cinnamon and molasses.

They offer a unique taste experience. Consumers enjoy them as a snack with tea or coffee. They are also popular during holidays and cold seasons. Their comforting warmth and aromatic spice make them a nostalgic favourite across generations.

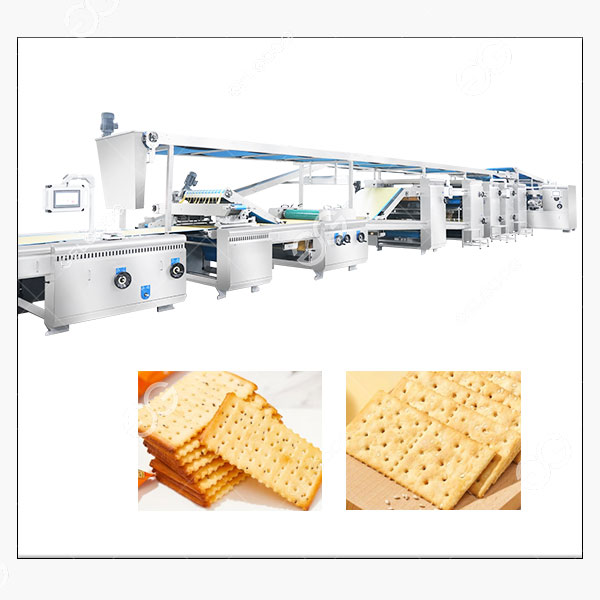

Features of Ginger Biscuits Production Line

- High Capacity & Efficiency: The line delivers a reliable output of 300-1200 kgs per hour. It meets the demands of growing markets. It maximizes your production potential.

- Multifunctional Design: This production line can produce various types of biscuits. It handles different shapes, sizes, and thicknesses. You can easily adjust it for new product development.

- Automated Control System: A central PLC control panel is the brain of the ginger nut biscuit production line. It allows for precise monitoring and adjustment of all parameters. This includes temperature, speed, and timing. It guarantees consistent product quality.

- Premium Construction: Built with high-quality stainless steel. This ensures durability and complies with international food safety standards. It is resistant to corrosion and easy to clean.

- Energy Saving Design: The line incorporates efficient motors and insulated ovens. It reduces overall energy consumption. This lowers your operational costs and environmental impact.

Machines For Making Ginger Biscuits

- Dough Mixer: This machine combines all raw materials uniformly. It creates a smooth, homogeneous dough. This is critical for consistent texture.

- Rotary Biscuit Moulder: This equipment imprints shapes and cuts the dough. It creates the classic ginger biscuit designs. And you can change the mold for different shapes.

- Tunnel Oven: The heart of the ginger biscuits production line. It bakes the biscuits with even heat distribution. It has independent temperature controls for each zone. This ensures perfect baking and colour.

- Cooling Conveyor: After baking, biscuits are brittle. This conveyor allows them to cool down slowly and evenly. It prevents breakage and sets their final crisp texture.

- Automatic Stacker and Packing Machine: This is the final step. It collects the cooled biscuits. It then stacks and packages them automatically. It ready for retail. Options include pouches or boxes.

Working Video of Ginger Biscuits Production Line

The ginger nut biscuit production line is a complete solution developed by our company. It is designed for quality, efficiency, and versatility. It transforms raw ingredients into packaged products with minimal effort. This line helps you increase output. It also ensures your products stand out in a competitive market.

Technical Parameters

| Model | Capacity | Inner Width of Tunnel Oven | Heating Method | Dimensions (without packing machine) |

Voltage |

| GG-BG400/420 | 100-250kg/h | 400/420mm | Electric,Gas | L45m*W5m*H2m | 380V 50HZ 3PH |

| GG-BG600 | 250-400kg/h | 600mm | Electric,Gas | L50m*W5m*H2m | 380V 50HZ 3PH |

| GG-BG800 | 500-800kg/h | 800mm | Electric,Gas,Diesel | L100m*W5m*H2.5m | 380V 50HZ 3PH |

| GG-BG1000 | 800-1000kg/h | 1000mm | Electric,Gas,Diesel | L105m*W12m*H3m | 380V 50HZ 3PH |

| GG-BG1200 | 800-1200kg/h | 1200mm | Electric,Gas,Diesel | L120m*W15m*H3m | 380V 50HZ 3PH |

Reviews

There are no reviews yet.