The goldfish crackers production line is an industrial equipment, it is suitable for large-scale business. It can automatically complete the entire process from raw material mixing to goldfish crackers packaging.

The entire line adopts a modular design and supports customized configuration to meet different production capacity requirements (100 to 1200kg/h), suitable for small and medium-sized food companies and large processing plants.

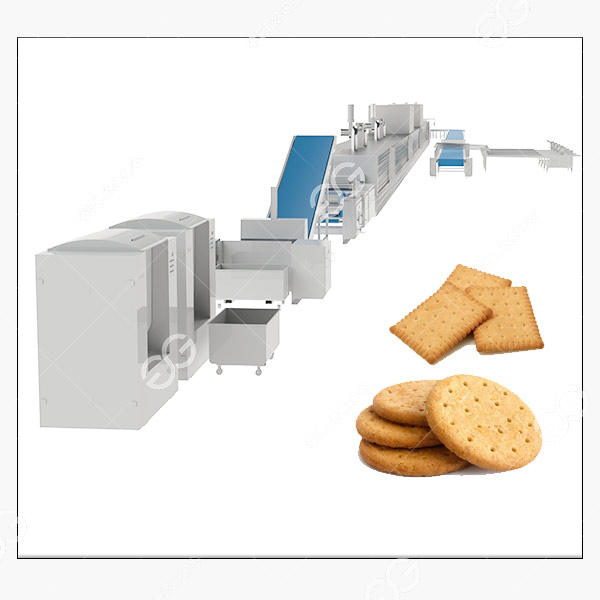

Main Equipment Components of the Goldfish Crackers Production Line

- Dough system: double-shaft mixer ensures that the dough is uniform and free of particles, equipped with temperature control function.

- Forming equipment: The mold presses out the goldfish shape, and supports quick mold replacement to adjust the product style.

- Tunnel oven: multi-layer baking structure, precise temperature control to make the goldfish crackers consistent in color and crispy in taste.

- Cooling conveyor belt: natural cooling to prevent the goldfish crackers from breaking and maintain the integrity of the finished product.

- Automatic packaging machine: optional bagging or boxing, integrated weight detection and metal detection function.

How Are Goldfish Crackers Processed?

- Mixing raw materials: The dough mixing system mixes flour, sugar, oil and other raw materials into a uniform dough.

- Pressing and molding: A mold presses the dough into the shape of a goldfish, and the system automatically recycles and reuses the scraps.

- Baking and shaping: The molded goldfish crackers are baked in sections at 160-300℃ in the oven to ensure crispness.

- Cooling and packaging: After the goldfish biscuits are cooled, they are automatically packaged by the packaging machine, and no human intervention is required throughout the process.

Goldfish Biscuit Production Line Application and Global Market Expansion

With its excellent stability and flexibility, this goldfish crackers production line has become the preferred equipment for global snack food manufacturers.

- In the Southeast Asian market, especially in countries such as Vietnam, Thailand and Indonesia, this line is popular because of its adaptability to high temperature and high humidity environments.

- Customers in the Middle East, such as food manufacturers in Saudi Arabia and the UAE, particularly favor its design that meets halal food standards and its high energy-saving performance.

- In African markets such as Nigeria, Kenya and South Africa, the equipment has helped local companies achieve the transformation and upgrading from manual production to industrialized manufacturing with its high cost-effectiveness and low maintenance costs.

- In addition, the goldfish biscuit production line has also successfully entered the South American market (such as Brazil and Mexico) and the Eastern European market (such as Russia and Poland) to meet the growing demand for local specialty snack foods.

International customers generally feedback that the production line not only significantly improves production efficiency, but its finished product qualification rate of more than 98% also greatly reduces raw material waste.

As the global snack food market continues to expand, this industrial goldfish crackers production line is constantly undergoing intelligent upgrades to further consolidate its leading position in the international market. Providing high-quality food machinery solutions to more customers.

Technical Parameters

| Model | Capacity | Inner Width of Tunnel Oven | Heating Method | Dimensions (without packing machine) |

Voltage |

| GG-BG400/420 | 100-250kg/h | 400/420mm | Electric,Gas | L45m*W5m*H2m | 380V 50HZ 3PH |

| GG-BG600 | 250-400kg/h | 600mm | Electric,Gas | L50m*W5m*H2m | 380V 50HZ 3PH |

| GG-BG800 | 500-800kg/h | 800mm | Electric,Gas,Diesel | L100m*W5m*H2.5m | 380V 50HZ 3PH |

| GG-BG1000 | 800-1000kg/h | 1000mm | Electric,Gas,Diesel | L105m*W12m*H3m | 380V 50HZ 3PH |

| GG-BG1200 | 800-1200kg/h | 1200mm | Electric,Gas,Diesel | L120m*W15m*H3m | 380V 50HZ 3PH |

Reviews

There are no reviews yet.