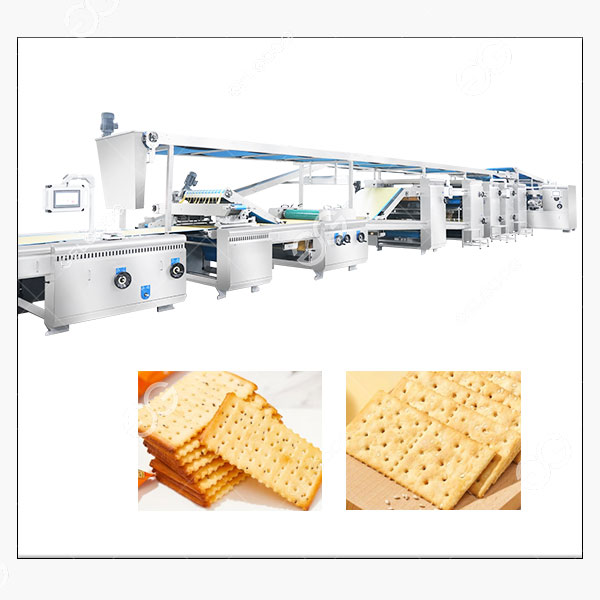

The soda cracker production line is a professional system specifically designed for efficient soda cracker manufacturing. It seamlessly integrates advanced technology with intuitive operation, ensuring the production of high quality soda crackers.

This production line operates fully automatically from dough preparation to final packaging. With its easy to use interface and reliable performance, it’s an ideal solution for food processing enterprises looking to produce a wide variety of soda crackers efficiently.

Main Machines of Soda Cracker Processing Line

- Dough Mixer: This machine efficiently blends ingredients to create a uniform dough with consistent texture and quality.

- Dough Roller and Sheeter: It flattens the dough into thin sheets with precise thickness control, preparing it for shaping.

- Cracker Forming: This machine forms the dough into the desired soda cracker shapes, such as squares or diamonds, with clean-cut edges.

- Baking Oven: Equipped with precise temperature and time controls, it bakes the soda crackers to achieve the good crispness and flavor.

- Cooling Conveyor: After baking, soda crackers pass through this conveyor to cool down, ensuring they maintain their texture and structure.

- Packaging Machine: It packages the finished soda crackers efficiently, ensuring product freshness and extending shelf life.

Video of Automatic Soda Cracker Production Line

Features of Soda Cracker Line

- Automated Operation: The production line features high degree automation, reducing manual intervention and ensuring consistent product quality.

- Precise Control: Advanced sensors and control systems ensure precise temperature, humidity, and timing control throughout the production process.

- High Efficiency: Designed for maximum output, this soda cracker processing line meets large scale production demands with minimal downtime.

- Easy Maintenance: Its modular design enables streamlined access to key components, simplifying cleaning and maintenance procedures and minimizing downtime.

- Energy Efficient: Featuring eco friendly motors and optimized systems, it significantly lowers long term operational expenses.

Advantages of Soda Cracker Production Line

- Consistent Quality: Every soda cracker boasts uniform shape, size, and texture, satisfying high – standard market demands.

- Reduced Labor Demand: Minimizes manual labor requirements, leading to considerable savings in labor costs.

- Economical Investment: Despite a higher initial cost, the soda cracker line cuts long term expenses through labor, raw material savings and waste reduction.

- Simple Operation and Monitoring: Features an intuitive control panel for easy operation and monitoring, lessening the learning curve for staff.

- Designed for Growth: The production line is easily upgradable and expandable to accommodate business expansion and changing market needs.

- Safe and Healthy Production: Engineered with food safety in focus, it meets stringent hygiene standards, ensuring safe and healthy soda crackers.

Our soda cracker production line for sale to many countries around the world. This equipment is good for food processing enterprises looking to enter or expand in the cracker biscuit market.

Whether you’re in North America, Europe, Asia, or any other region, our professional team will provide comprehensive support, including installation guidance and after sales service.

Technical Parameters

| Model | Capacity | Inner Width of Tunnel Oven | Heating Method | Dimensions (without packing machine) |

Voltage |

| GG-BG400/420 | 100-250kg/h | 400/420mm | Electric,Gas | L45m*W5m*H2m | 380V 50HZ 3PH |

| GG-BG600 | 250-400kg/h | 600mm | Electric,Gas | L50m*W5m*H2m | 380V 50HZ 3PH |

| GG-BG800 | 500-800kg/h | 800mm | Electric,Gas,Diesel | L100m*W5m*H2.5m | 380V 50HZ 3PH |

| GG-BG1000 | 800-1000kg/h | 1000mm | Electric,Gas,Diesel | L105m*W12m*H3m | 380V 50HZ 3PH |

| GG-BG1200 | 800-1200kg/h | 1200mm | Electric,Gas,Diesel | L120m*W15m*H3m | 380V 50HZ 3PH |

Reviews

There are no reviews yet.